Welcome to the basement

A brother from another mother worked at a place where they used a laser to cut various pieces parts from different sheets of steel of assorted thickness.

A brother from another mother worked at a place where they used a laser to cut various pieces parts from different sheets of steel of assorted thickness.

Pretty cool in my opinion. This is an example of the intricasies available when writing a program for a laser to cut an eagle from an 18ga slab of steel

Another nice example is the logo to the company he had worked. I say "worked" because he is now retired. I found these items in the box with the furnace tags and I'm pretty sure they're the last ones left. These were made back around 1990 – 1992, one reason they're a bit spotted and not the shiny new steel they once were.

Another nice example is the logo to the company he had worked. I say "worked" because he is now retired. I found these items in the box with the furnace tags and I'm pretty sure they're the last ones left. These were made back around 1990 – 1992, one reason they're a bit spotted and not the shiny new steel they once were.

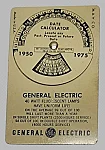

Here's an interesting gizmo. I found it in the return box on the side of an old Sunbeam gas furnace. It was covered in dirt, hair, goop from excess oil. It cleaned up well so I added t with my tag collection.

Turn the dial for a month to point to a year, read the window and calculate what day of the week and it's number assignment. It works from 1950 – 1975. They were passed out as pocket advertisments back in the early to mid 1960's.

Shout out to the brothers and sisters affiliated with the SMART union and more specifically to the folks who are part of the Sheetmetal Workers Local #33.

Shout out to the brothers and sisters affiliated with the SMART union and more specifically to the folks who are part of the Sheetmetal Workers Local #33.

Caveat emptor

After talking with a friend of mine, he suggested that I include some form of disclaimer to protect myself from people out there who attempt to profit through [intensional] misunderstanding or [deliberately] misapplying information that may be viewed, read, or obtained via download, so without further ado:

I make no representation or warranty of any kind, express or implied, regarding the accuracy, adequacy, validity, reliability, availability, or completeness of any information presented on this webpage, on this website, or on this domain.

With that statement being made, the following information is not of my invention and all of it would be easily obtained with the possible exception of R‐454b refrigerant weigh‐in values which were obtained via email with an engineer at Chemours. I was taught the ductwork rule of thumb by others; it has been around a lot longer than I. So whether you use the information presented or not that's up to you, I find it eases stress and can reduce confusion.

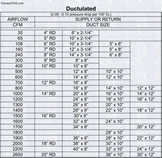

Residential ductwork Rules of thumb

Pretty simple just remember:Times two Plus two (x2 +2)

That's for every 6in round run. 7in count as 1-1/2 times and 8in count as two

Example:

Let's say there are 14 6in SA's in the house.

Let's assume the furnace sits in a basement at one end so the ducts run to the opposite end.

Two SA's come directly off the plenum, all remaining take-offs are on the ductwork.

We'll ensure good airflow at furthest take-off by staging our ductwork with one reducer.

We start off with 14 - 2 (plenum SA) = 12 (SA on duct)

12x2=24+2=26 (8)

We could use 26x8 duct or 20x10 duct to start.

We'll select 20x10 and run it connecting 8 SA's leaving 4 SA's remaining.

4x2=8+2=10 (8) duct is our reduce size.

At this point, we fabricate a 20x10—10x8 reducer.

Run our 10x8 duct connecting the remaining 4 SA's.

Note: Always leave a minimum of 12in duct between last take-off and end cap for ductwork to pressurize.

Return Air

Our return air duct should be 2in larger than SA so we would have either 28x8 or 22x10 at our furnace and reduce down midway to 16x8 to pick up the last 3 or 4 return pathways.

another scenario

14 6in SA's, furnace sits in center of basement, two SA's come directly off plenum leaving 12 runs, 6 SA's for each duct.

6x2=12+2=14(8) So we run 14 (8) duct off plenum in each direction, reduce after 3 SA's are connected leaving 3 to go:

3x2=6+2=8 (8)

So we make a 14x8—8x8 reducer. We run the 8(8) duct for the remaining 3 SA's, again ensuring at least 12 inch dead space between end cap and last take-off.

Fair use

Fair use

I've always believed in giving credit where credit is due and I've attempted that through sourcing my references with links where appropriate. Much information is obtained through search results using either DuckDuckGo or Google. When articles exist online I link back to that source for either cited text or graphical usage, in many cases information resides in the public domain and can be found on the Internet Archive (archive.org) which is also cited with links.

IF for some reason I've quoted text or used an image that falls under copyrighted material, it is not my intent to "steal" that information. It was acquired through research in an attemp to educate people on the past history of furnaces, air conditioning (winter and summer), and auxillary equipment used primarily in the residential HVAC industry and as such I claim fair use.

Construct

Construct

This site built with HTML5, CSS3, on a Windows10 box using Notepad for basic editing, Bluefish for semantic proof reading, XAMPP for local testing, W3Schools and MDN for coding references. Images were photographed with my Samsung Galaxy S22 Ultra, edited with Macromedia Fireworks 8 (I'm old) and then converted to the WebP format using Irfanview. The font used on this website is: Noto Sans.

note:

There are NO web beacons (web bugs), tracking scripts, browser fingerprinting, etc. to determine from where you came, what you're looking at, or where you're going — I simply don't care. There is nothing on this site that would require something to be written on your local storage for current or future views (cookies). There are no forms to fill out, no methods to gather your name, IP, email, or other personally identifiable information – don't need it, don't want it.So enjoy your stay and please leave it the way you found it. ;-)

Vintage advertisements

Vintage advertisements

Throughout the pages of these old furnace tags you'll come across many vintage advertisements scrapped from old magazines such as National Geograhic, Look, Life, and Time to name but a few. I discovered these while researching and was amazed at how many of these old ads exist, most of which are for sale on eBay or Amazon, or elsewhere. If any of you are intrigued with them use your favorite search engine or search sites like eBay directly and snag a few for yourself. Collecting advertisements for some would be like the tags I've collected through my lifetime.

Hello. My name is Dave and I'm pleased to meet you.

Hello. My name is Dave and I'm pleased to meet you.